Our focus on precision, flexibility, and good quality makes certain dependable PCB assemblies, from prototypes to significant generation volumes Make contact with us right now to discuss your venture and find the Adonai benefit!

We aren't talking about one machine. Up to six (six) machines are used to facilitate The location of Digital parts within the circuit boards.

speedy starting to be a development within the electronics production marketplace. That is relevant due to the should reduce expenses, Enhance the velocity of output and get rid of a lot of the difficulties that restrict improved effectiveness of creation.

Yamaha Motor also beats the opposite SMT machine manufacturers to your Opposition by supplying competitive charges.

This SMT machine is primarily useful for enabling solder reflow within the Surface Mount System (SMD) into the circuit board. This really is performed following the reflow soldering is finished with solder paste.

This convection reflow oven is ideal for mid-to-high volume guide-absolutely free soldering production lines. eight higher and 8 bottom compelled incredibly hot air convection zones make it possible for high quality lead-free of charge soldering with uniform heating and Remarkable system balance Temperature precision of ±1°C along with a superior-pace CE certificated blower for max convection

The smt machine quantity of production also determines the opportunity of combining the trio of solder paste baking, adhesive curing, and solder reflow.

Besides, the IPC 9850 speed or ranking standard has to do with the overall pointers for that circuit board arrays and the section mix.

Hot Bar soldering, generally known as pulse heat thermode or pulse bonding, is used to be part of two sections collectively by melting solder in between them to form a long lasting electromechanical bond. The top to melt the solder is produced by thermode’s resistance to electrical present. $four,500.00

Just about the most essential ways that affects the concluded high quality of circuit boards is the appliance of solder paste, Solder paste software is The main element process in board assembly operations working with SMT techniques.

The machines that we offer were being created for amenities needing fast set-up, ease of operation, and significant reliability in minimal to medium quantity pick & area applications.

A reflow oven is often a machine utilized largely for reflow soldering of surface mount Digital factors to printed circuit boards.

The main SMT machine For brand spanking new manufacturing unit, I recommend a 6 heads choose and palce machine PPM-C400GS+. As manufacturing capacity requires maximize, new six-head or 8-head placement machine may be seamlessly built-in into the prevailing creation line to boost efficiency and throughput, as illustrated during the figure below.

This automation lowers guide dealing with, minimizes the chance of harm to sensitive factors, and increases In general performance.

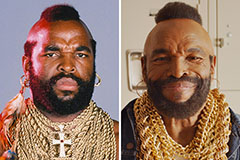

Mr. T Then & Now!

Mr. T Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Barry Watson Then & Now!

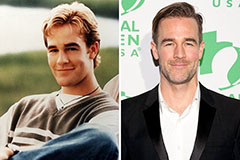

Barry Watson Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now!